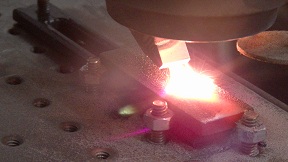

Titanova Diode Laser Cladding Capabilities

Titanova brings years of expertise in the area of diode laser cladding to industry. This welding process makes use of customized diode lasers to create the thinnest and purest weld overlay achievable. No other welding process comes close to the quality that diode laser cladding offers.

This process permits the modification of the surface metal chemistry of functional parts without a significant amount of weld distortion or heat-affected zone. The surface modification benefits are for corrosion or erosion or both. For surface corrosion Titanova, Inc offers laser cladding of corrosion resistant alloys such as all varieties of stainless steels [300 series and 400 series], nickel and chrome based superalloys

[Inconel™ and Hastalloys™]. For wear resistant protection, Titanova can laser clad a variety of cobalt-6 alloys [Cobalt-6™], iron chrome carbide, and ceramic metal matrix materials such as chrome carbide and tungsten carbide, in a self fluxing Ni-Cr-Si-B metal matrix.