Titanova Diode Laser Alternative – Fills a Gap Without Distortion

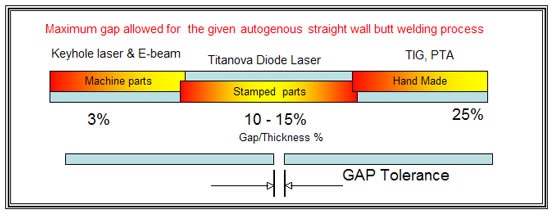

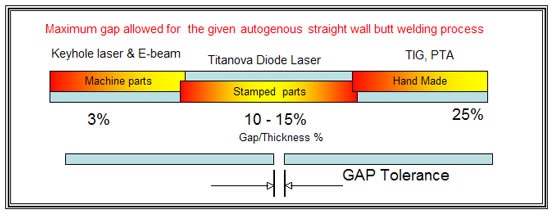

The amount of melted material is directly related to the amount of distortion. The Titanova diode laser welding process fills a welding fit-up gap tolerance requirement window between traditional TIG and PTA and the “keyhole” processes such as laser and E-beam. The diode welding process is about 3X – 5X more forgiving with respect to part fit-up as compared to traditional key-hole welding processes. Therefore we can butt weld very thin gage materials, 28 – 36 gauge, even foils consistently.

E-Beam And Keyhole Laser Welding

Typical process speeds achieved with diode laser are 3 X better than TIG or PTA. Since the weld nugget is smaller, the distortion is also improved significantly thus allowing for thinner gauges while simultaneously eliminating post processing.

Why is this important to the machine shop customer?

State of the art CNC based metal process machinery such as punch presses, tube benders and press breaks are now, and have been for some time, accurate enough to allow for diode laser welding. Therefore one can weld much faster and with much less distortion without changing upstream stamping or fixturing processes

Wire Feed Laser Welding

Titanova, Inc. is the only US contract manufacturer offering direct diode laser systems that can be used with a wire feeder. We offer both hot and cold laser wire feed welding. The advantages are increased throughput, less weld distortion, excellent quality, and quick turn-around time. Titanova is the only laser job shop offering this unique service.

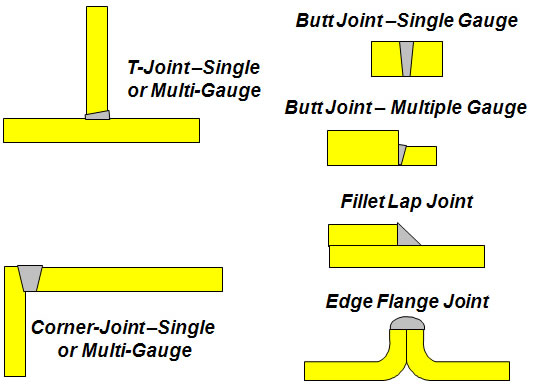

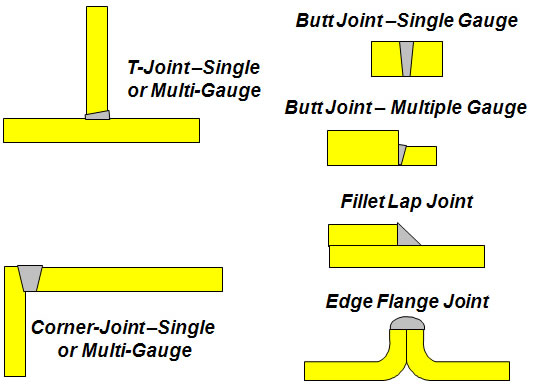

Examples of Weld Joint For Autongenous Welding