The Greatest Benefit

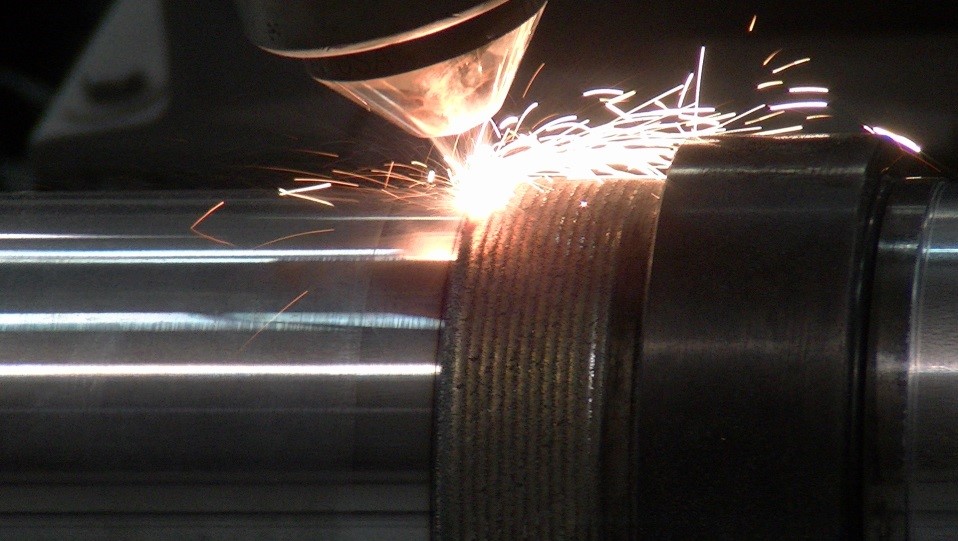

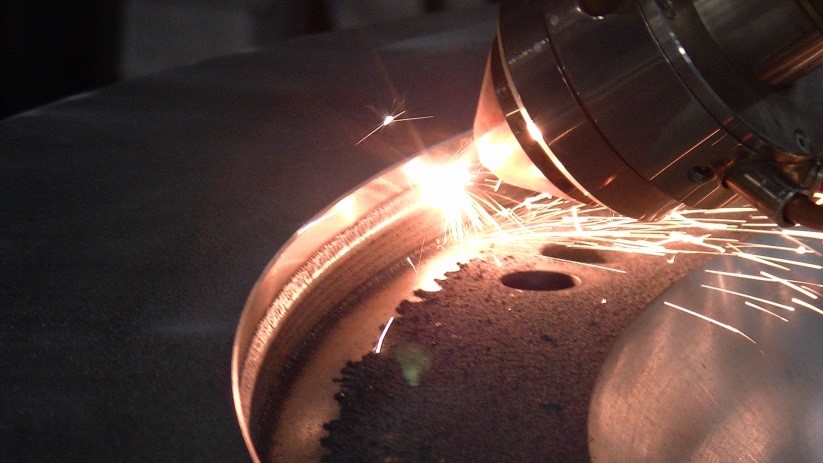

The greatest benefit of direct diode laser cladding is the low heat input significantly reducing amount of heat distortion. Other benefits include reduction of pre-machining and post-machining requirement due to the very small amount of dilution and heat effect zone

Unlike traditional overlay techniques the laser diode reman doesn’t create a hard zone in the immediate vicinity of the clad and base metal interface due to dilution. This hard zone precludes the much greater pre machining such that the clad hardness is uniform for subsequent post machining.